Watts Big Bubba Housing BBH-150 - #PWWJCHSG

Watts Big Bubba Housing BBH-150 - #PWWJCHSG | List Price: CDN$ Our Price: CDN$1,582.30 You save: $316.46 Write a review. Found a Lower Price? Request a Price Beat |

|

Special Order Item.

Please contact us for lead time.

Note: Filters sold separately.

- Description

- Specifications

- Available Cartridges

- Installation / Manual

- Reviews

Watts Big Bubba filter housings are made of rugged, glass-reinforced polypropylene so they will not chip, rust or dent. All wetted surfaces are non-metallic, so they are ideal when chemical compatibility is an issue or for sea water applications.

They are an economical replacement for stainless steel filtration equipment because of their non-metallic construction and today’s high cost of stainless steel!

Watts® Jumbo Cartridges are ideal for a wide range of applications, including:

- Whole house filtration

- Commercial filtration

- Industrial filtration

- Pre-filtration for reverse osmosis equipment

- Community water systems

- Sea water applications due to their non-corrosive construction

- Ideal replacement for bag filters

- A convenient alternative to multiple cartridge filters

- Water for livestock and poultry

Watts Big Bubba Housing BBH-150 Specifications

| Technical Specifications | |

|---|---|

| Part # | #PWWJCAC5 |

| Body (all wetted surfaces) | Glass reinforced PP |

| Gauge port | 1/4" FNPT brass reinforced |

| Cartridge end caps | Glass reinforced PP |

| O-rings | EPDM (Viton optional) |

| Pipe fittings | 2" slip |

| Overall height | 42.7" |

| Width (vessel OD) | 15.4" |

| Maximum temperature | 125°F (52°'C) @ 80 PSI |

| Maximum working pressure | 125psi (8.75 bar) |

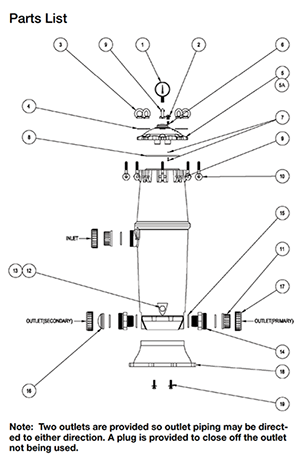

| Item # | Description |

|---|---|

| 1 | 1/4" Pressure Gauge |

| 2, 6 & 7 | Pressure relief assembly includes cap, spring and stem |

| 2 | Pressure release button |

| 3 | Wing Nut |

| 4 | Washer for lid closure |

| 5 | Lid with brass reinforced gauge port |

| 5A | Lid without brass reinforced gauge port |

| 6 | Pressure relief spring |

| 7 | Lock pin with O-ring |

| 8 | O-ring for lid closure, EPDM |

| 9 | Stud for eye bolt |

| 10 | Eyebolt |

| 11 | Adapter 2" PVC |

| 12 | Drain plug 1/2" NPS without O-ring |

| 13 | Drain plug O-ring |

| 14 | Coupler |

| 15 | Coupler O-ring |

| 16 | Plug for second outlet |

| 17 | Nut for plumbing adapter |

| 18 | Base |

| 19 | Mounting Bolts |

Installation Procedures

Install filter housing using the appropriate size pipe. (Pipe fittings are 2" slip). Follow the PVC glue and primer manufacturer’s instructions when making all solvent weld connections. Be sure to install shutoff valves before and after the filter housing and on any drain connections, which are to beinstalled. A 1/4" FNPT port is located on top of the filter's lid, and a pressure gauge has been provided. Locate this gauge (in carton) and install it in gauge port using Teflon tape. A second gauge may be installed; downstream of the filter (in the pipe line) to indicate pressure differential and help you determine when cartridge replacement may be necessary.

Vent and Pressure Gauge

A 1/4" FNPT port and pressure gauge has been installed in the filter's lid to indicate working pressure. A second gauge may be installed, downstream of the filter in the pipe line to indicate pressure differential and help determine when cartridge replacement may be necessary.

Initial Start Up

Once the piping procedures are completed, shutoff valves have been installed and the cartridge has been inserted and locked in place, open outlet completely, start up pump and open inlet valve slowly to check for leaks. If leaks occur, shut off pump, close inlet and outlet valves, release pressure by pressing pressure release button, remove lid and check the O-ring to be sure it is properly seated.

Caution

Do not attempt to remove lid without relieving pressure. To open lid, close shutoff valves before and after filter, press pressure relief button to relieve pressure. Once pressure has been relieved, remove eyebolts and lid. To start up filter, replace lid, tighten eyebolts, and open shutoff valves slowly to check for leaks. If lid O-ring does not seat properly, close shutoff valves, relieve pressure, open lid, apply a small amount of non-petroleum based lubricant to the O-ring to help it seal, reposition O-ring and close lid.

Do not operate filter above 125psi (8.8 bar). In installations where pressure is above 100psi (6.9 bar), install a pressure release valve to release pressure at 125psi (8.8 bar) or less.

Parallel Installation

Parallel installations are recommended to achieve high flow rates, by installing filters on a common manifold, feeding all filters installed in a row.

Series Installation

Series installations are recommended for applications such as surface water filtration, where cartridges having different micron ratings are used.

Watts Big Bubba Housing BBH-150 - #PWWJCHSG Reviews

There are currently no reviews for this product.

Be the first to write a review.